MECHANICAL ENGINEER WITH HONORS, ESKISEHIR OSMANGAZI UNIVERSITY

+90 531 886 64 17

+90 531 886 64 17 linkedin.com/in/yusuf-cubukcu/

linkedin.com/in/yusuf-cubukcu/ yusufcubukcu1998@gmail.com

yusufcubukcu1998@gmail.com

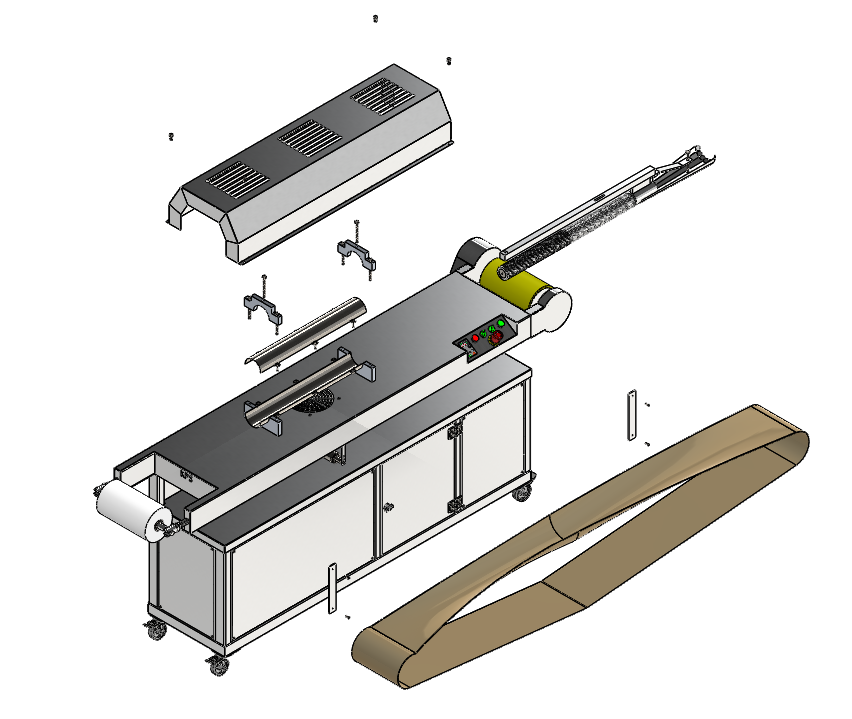

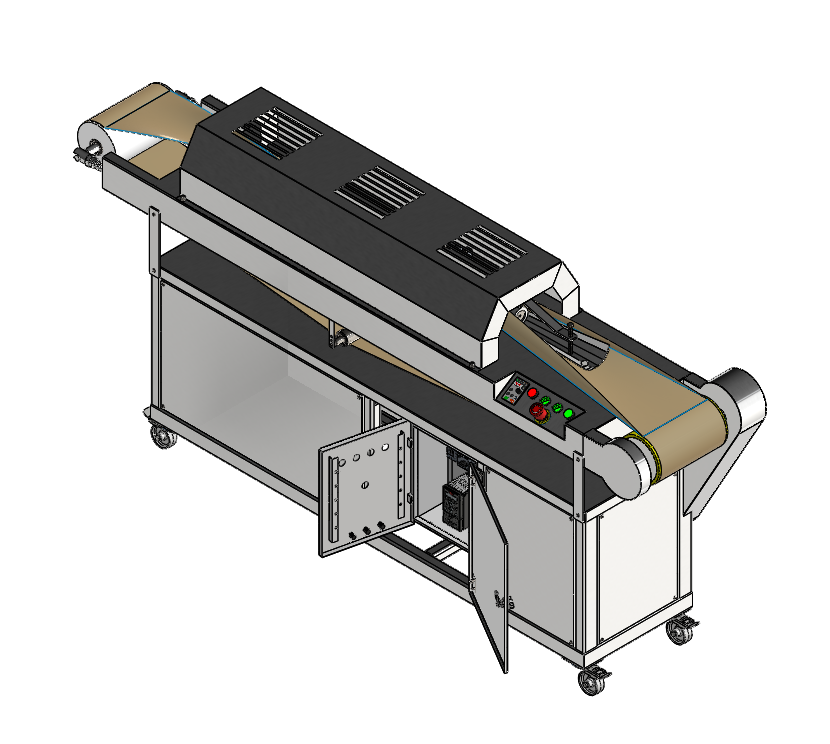

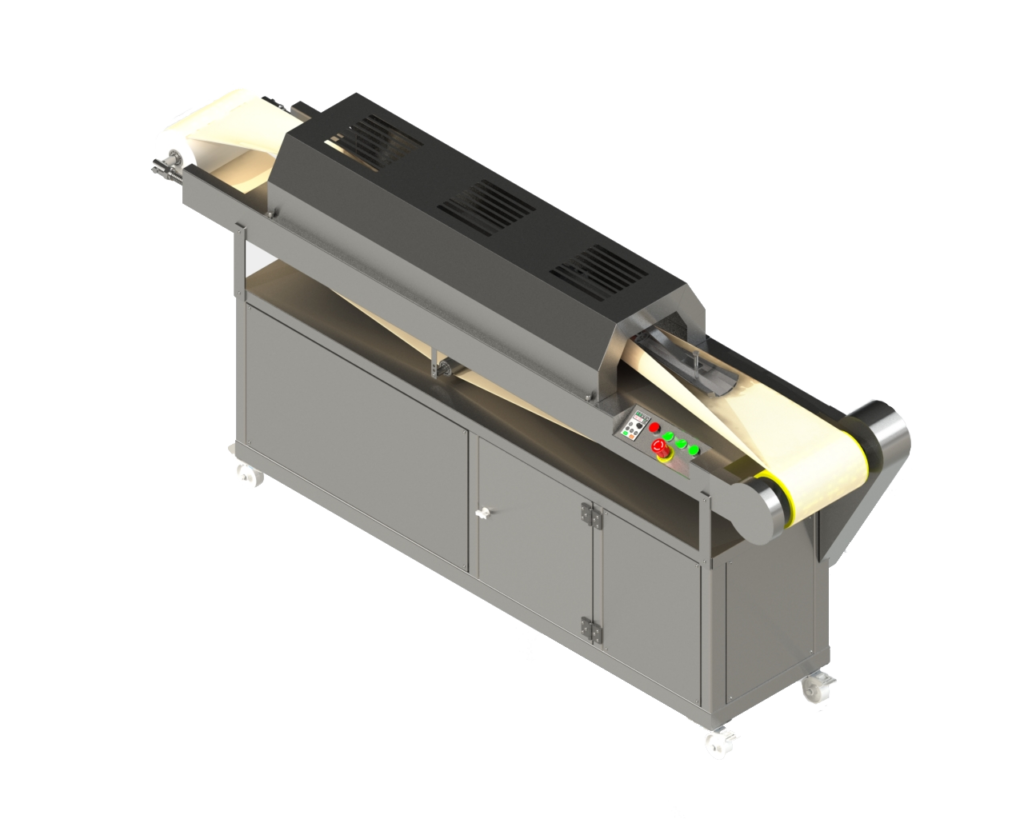

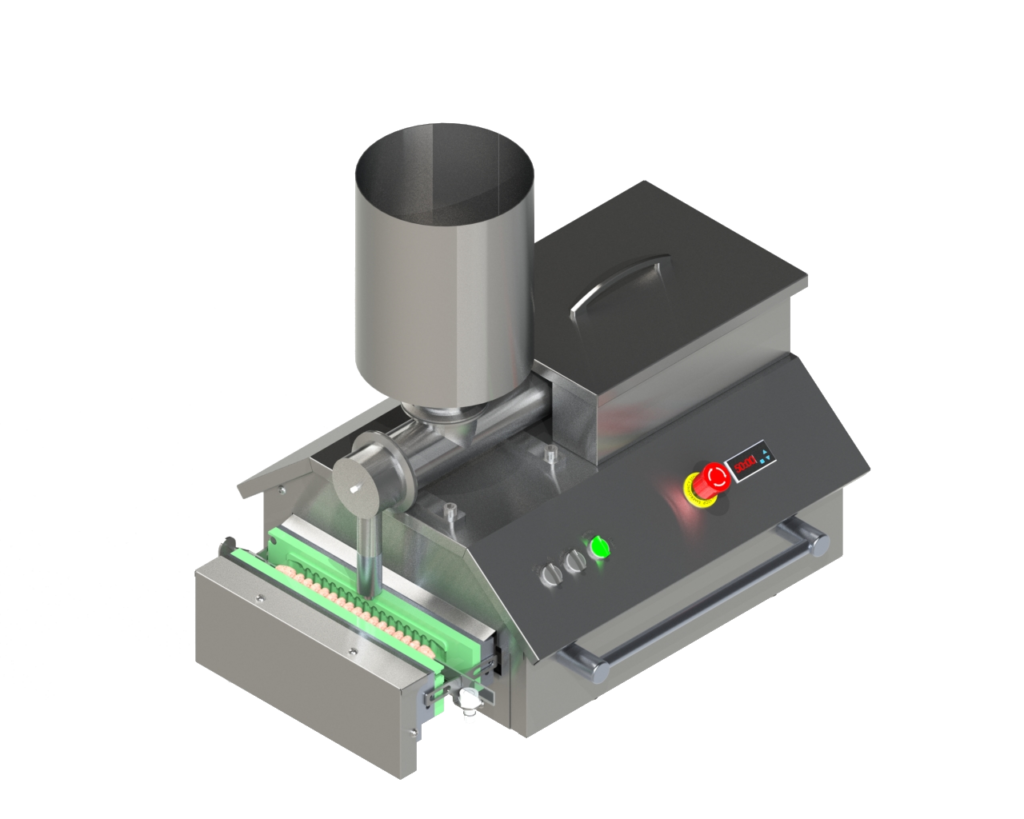

BAGEL MACHINE - KOPUZ

What ?

- A machine to shape dough strands into bagels.

- The goal was to improve the machine and reduce manufacturing costs while improving its performance.

How ?

- The machine’s structure and many of its components were modified using SolidWorks. (sheet metal and weldments features).

- Applied GD&T on all drawings.

- Supervising assembly operations.

Results

- Reducing the machine’s lengh by 50 cm has provided us with more workspace.

- We achieved a 20% reduction in production costs.

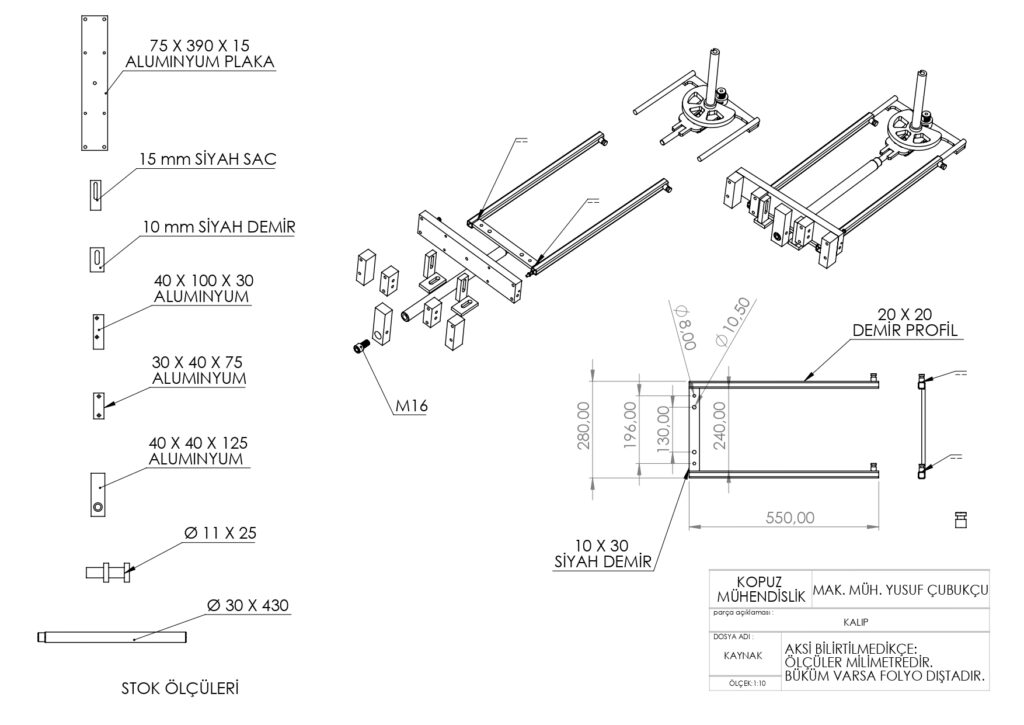

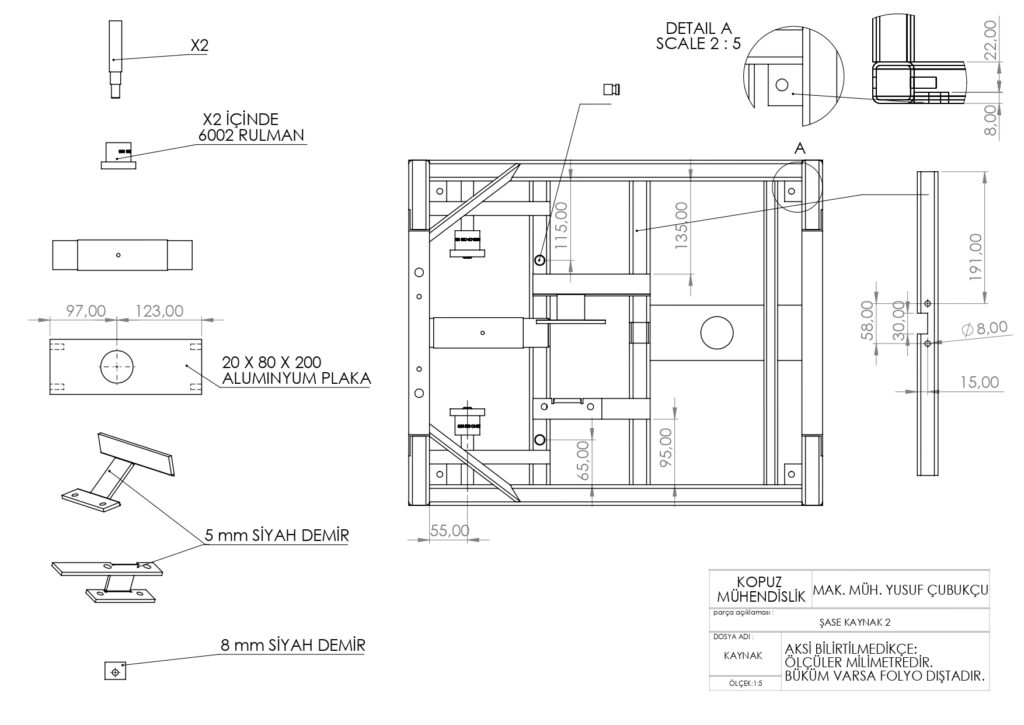

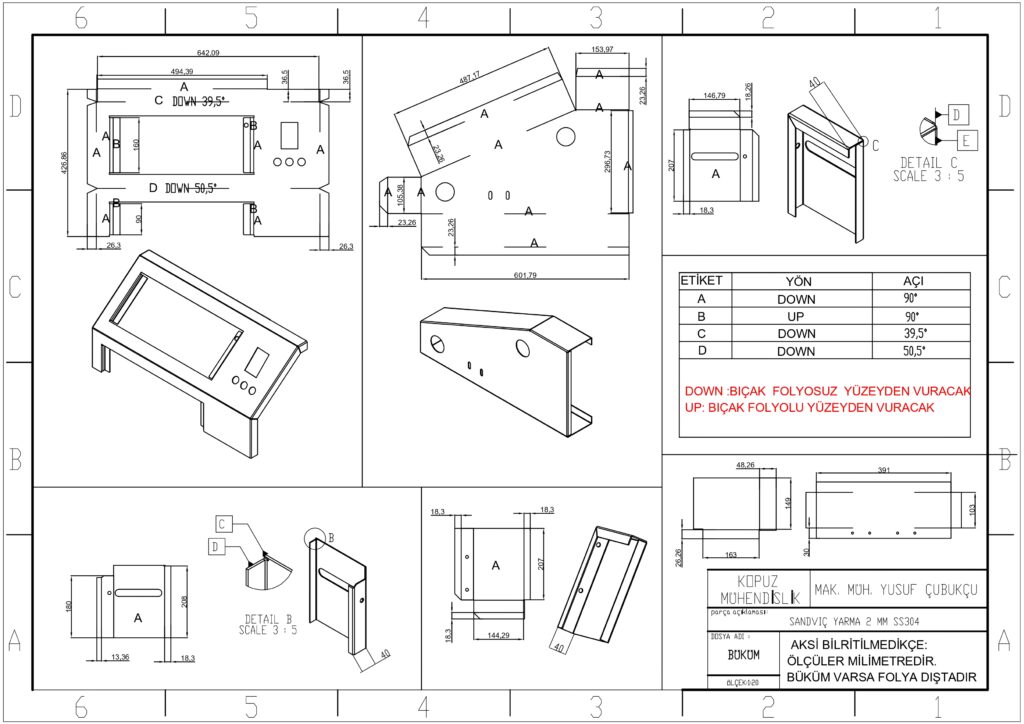

Automatic kebab skewering machine - KOPUZ

What ?

- The order was to generate a comprehensive manufacturing production file following the machine modification, as the original file had become damaged and unsuitable for the purpose.

How ?

- A comprehensive SolidWorks model of the machine was created, incorporating weldments and sheet metal components.

- Detailed engineering drawings were produced for each part, including separate files for fabrication processes like welding, turning, milling, and assembly.

- AutoCAD was used to organize sheet metal parts based on their thickness and material.

Results

- Developing a production method that relies on bending instead of welding in certain parts.

- Accelerating the production process by 20% and significantly organizing the workflow.

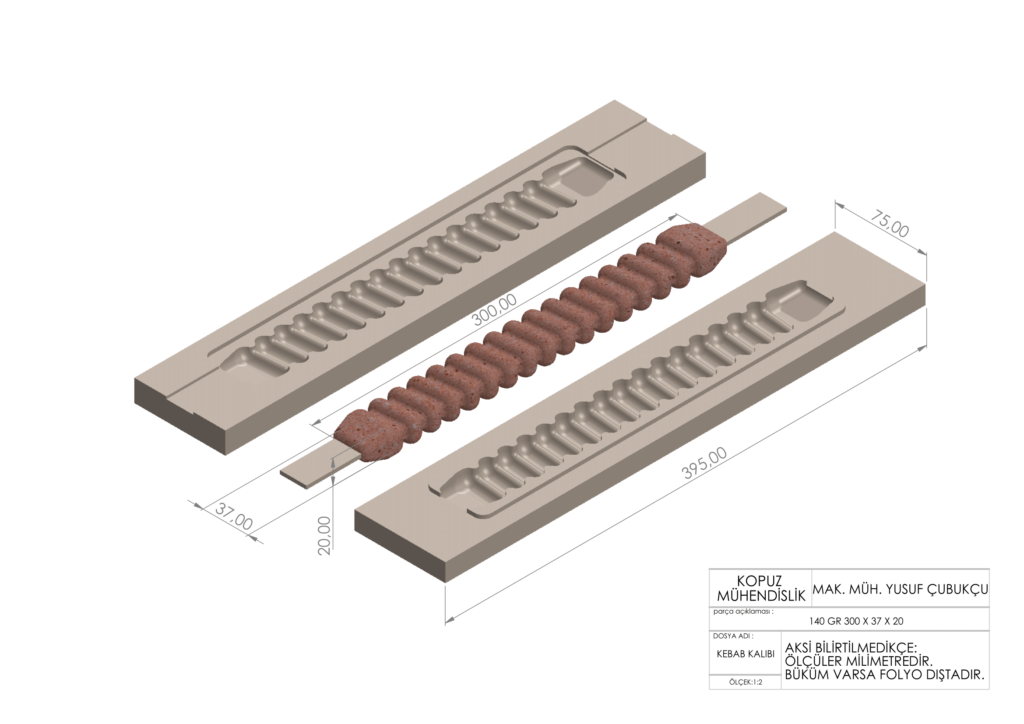

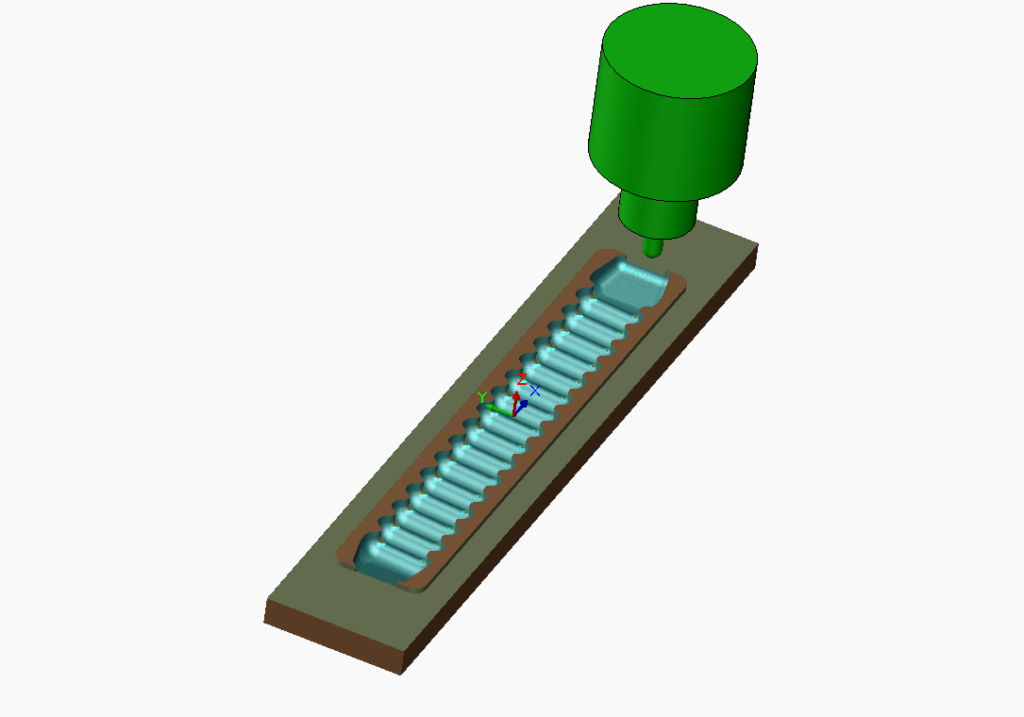

KEBAP MOLD - KOPUZ

What ?

A kebab mold designed for a kebab skewer machine, capable of holding between 80 and 180 grams of beef, depending on customer request.

How ?

- Designed using SolidWorks.

- Capacity was also calculated within the software by specifying a material density equivalent to ground beef (1.027 kg/m³)

- . The raw material is 6000 series aluminum and will be coated with Teflon post-production.

- A CNC milling machine using SINUMERIK 828D control was programmed with code generated directly from SolidWorks CAM to manufacture the mold.

Results

- The design achieved its purpose with an accuracy of 96% ( with a tolerance of no more than 5 grams for a 140-gram mold).

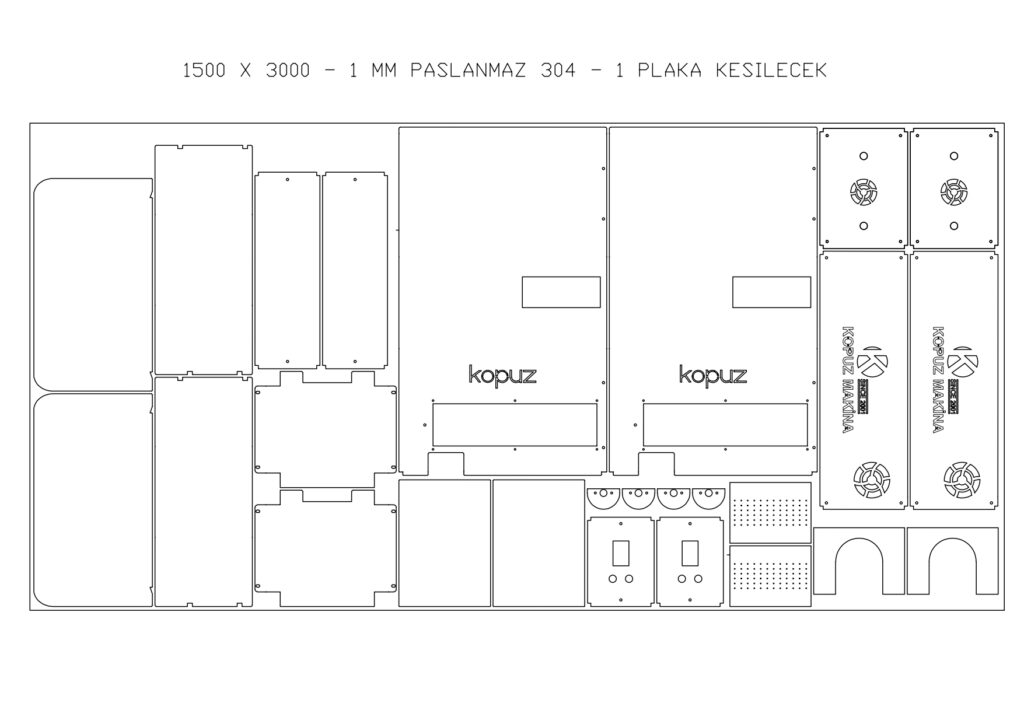

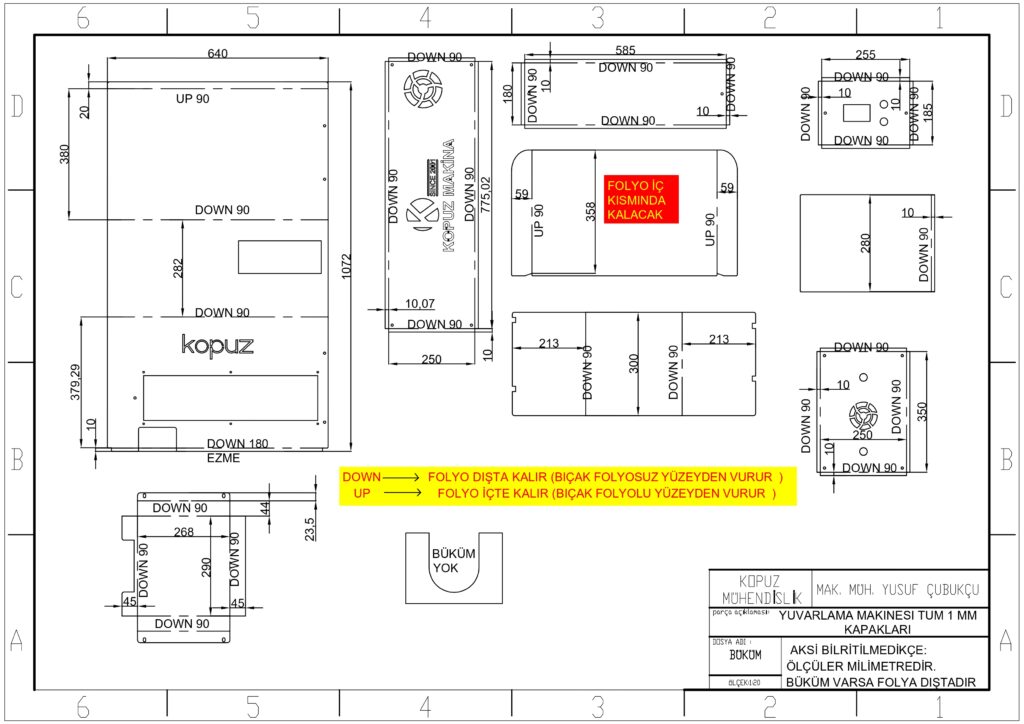

Sheet metal operations management - KOPUZ

What ?

Attempting to place each machine’s parts individually on a single sheet of metal to prevent the loss of any machine parts, avoid the overlapping of different machine parts,

and create technical drawings for bending in the same manner.

How ?

- Flat patterns were nested in AutoCAD on a 1500x3000mm sheet and modeled in SolidWorks.

- Drawings were sent to the sheet metal workshop.

- Bending was supervised for critical or complexed parts.

Results

- Organizing the manufacturing process more efficiently and reducing the problem of missing specific machine parts in urgent orders.

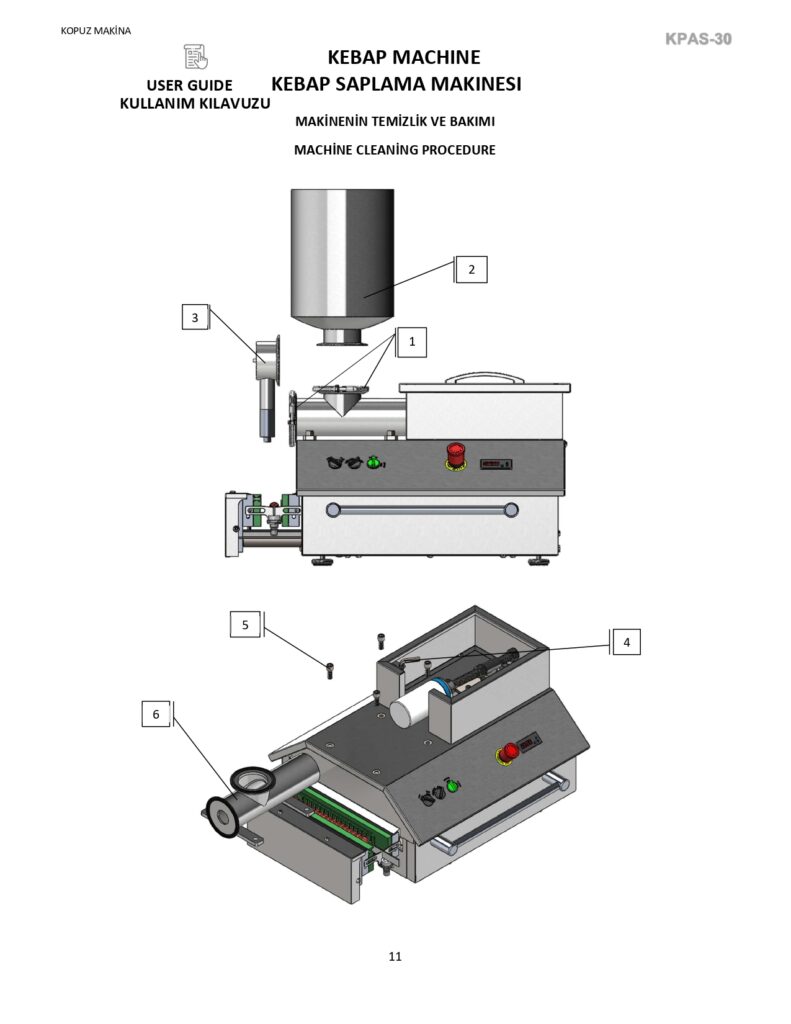

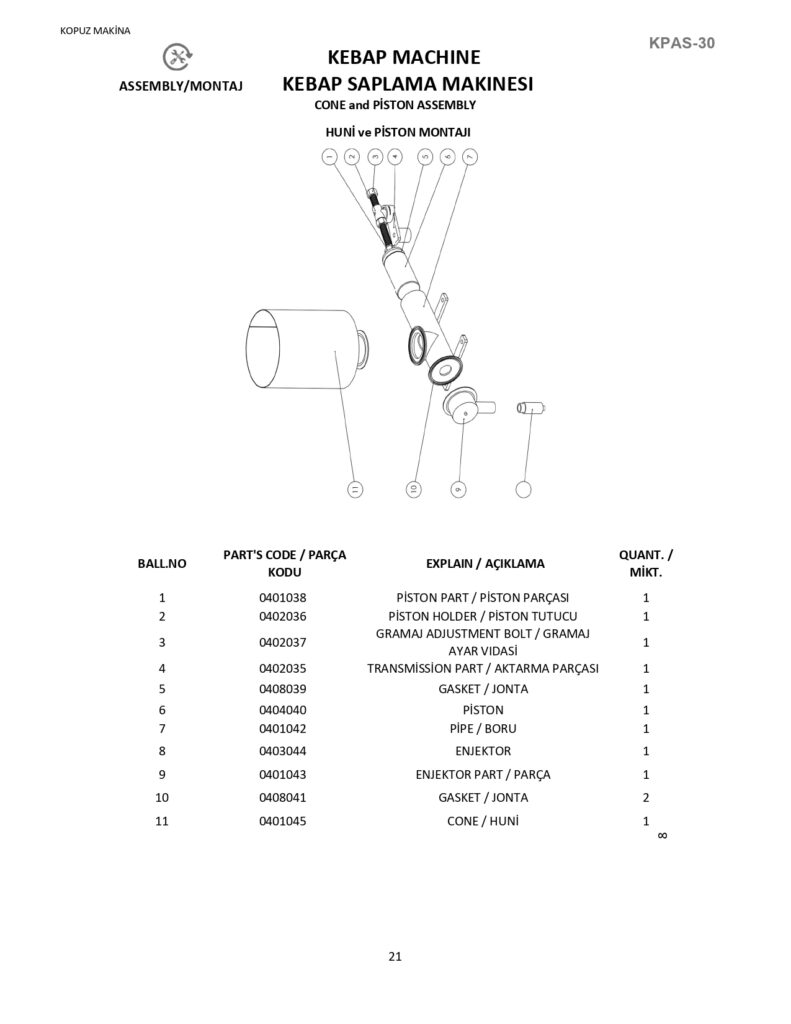

Individual user manuals for each machine - KOPUZ

What ?

After modifying and upgrading some machines, we noticed that the user manuals did not match the new equipment. Therefore, I created new manuals that are consistent with the modified machines.

How ?

The supporting images were generated using SolidWorks rendering and technical drawings, and formatted in a Word document. The following points were considered:

- Logical arrangement and detailed index

- Safety warnings, instructions, and emergency procedures.

- Ease of use.

- Parts list.

Clarity and comprehensiveness of information.

Results

A high-quality user manual has been acquired to optimize both our time and the user’s time.

The manual contains all the necessary information to safely and efficiently operate and maintain the device.

The complete user manual is available for your perusal here.

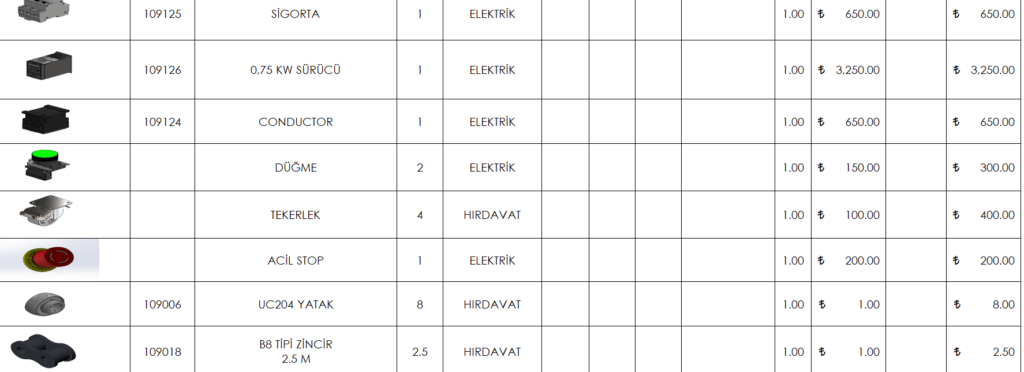

Manufacturing cost table for the machine - KOPUZ

What ?

After manufacturing some new machinery and experiencing significant price variations in the market, we needed a consistent pricing table that aligns with our product requirements.

How ?

- A Bill of Materials (BOM) table was created using SolidWorks and linked to Excel cells. Multiple sheets were generated, each representing a different machine. All corresponding cells were linked to a single price cell, allowing for the price of a component to be updated across all machines by modifying only one cell (the price cell).

Results

- A BOM has been obtained that contains all the components and parts necessary for manufacturing the machine. It provides vital information about the machine’s composition, aiding in planning for purchasing, manufacturing, and assembly. It can be easily and simply kept up-to-date.